Key Features of KGN Engineerings’ Plastic Pallets for Pharma

1. Hygienic and Non-Contaminating Design

Our plastic pallets are made from high-quality, virgin-grade polymers that do not absorb moisture, odors, or chemicals. This ensures they remain non-contaminating and easy to sanitize, maintaining the sterile conditions required in pharmaceutical manufacturing.

2. Durable and Long-Lasting

Unlike wooden pallets that splinter or metal pallets that corrode, our plastic pallets are corrosion-proof, impact-resistant, and highly durable. They can withstand heavy loads, frequent cleaning, and harsh working conditions without deforming or degrading.

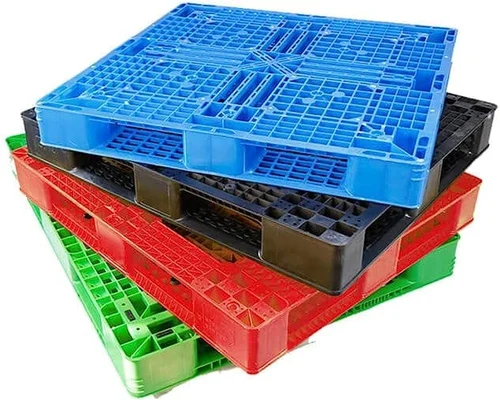

3. Lightweight and Easy to Handle

The lightweight nature of plastic makes these pallets easy to handle, stack, and transport, reducing operator fatigue and improving workflow efficiency.

4. Smooth and Non-Porous Surface

A major advantage of our plastic pallets is their smooth, non-porous surface that prevents dust accumulation and bacterial growth. This feature makes them ideal for cleanroom and sterile production areas.

5. Resistant to Chemicals and Moisture

The pallets are resistant to chemicals, acids, and moisture, ensuring they remain stable and reliable even in environments exposed to cleaning agents or controlled humidity.

6. Recyclable and Eco-Friendly

At KGN Engineerings, we care about sustainability. Our pallets are made from 100% recyclable plastic, making them an environmentally responsible choice for modern pharmaceutical industries.

7. Anti-Slip and Stackable Design

Our pallets feature anti-slip surfaces and interlocking structures that provide stability when stacking or transporting materials, minimizing the risk of accidents and product damage.